2016 Mazak VTC 800/30SR

2016 Mazak VTC 800/30SR

Description

The Mazak VTC 800 series is a line of powerful, large-format 5-axis turning centers for large workpieces, known for their high precision and rigidity, ideal for aerospace, energy and heavy machinery, with functions such as integrated spindles, fast tool change, and for efficient complete processing. Accessories/Options:

Tool magazine for 30 tools

Tool length measurement, tool breakage detection

Factory-installed preparation for chip conveyor (left)

Magazine (HSK) for 155 tools

Air blower at the workpiece

Signal light (end of machining: yellow)

Additional: Work area lighting

Coolant gun

Air blower through the spindle

70 bar preparation, including interface for high-pressure system

Automatic opening/closing of the operator door

Mazak Monitoring System B RMP 60 (only/H/V)

Collision monitoring by Brankamp

2 Renishaw TS27R tool presetting devices

NC rotary table

Holding device for vertical use of the NC rotary table

Table center partition for pendulum machining

3D model of the work area in STEP format

5-axis milling technology

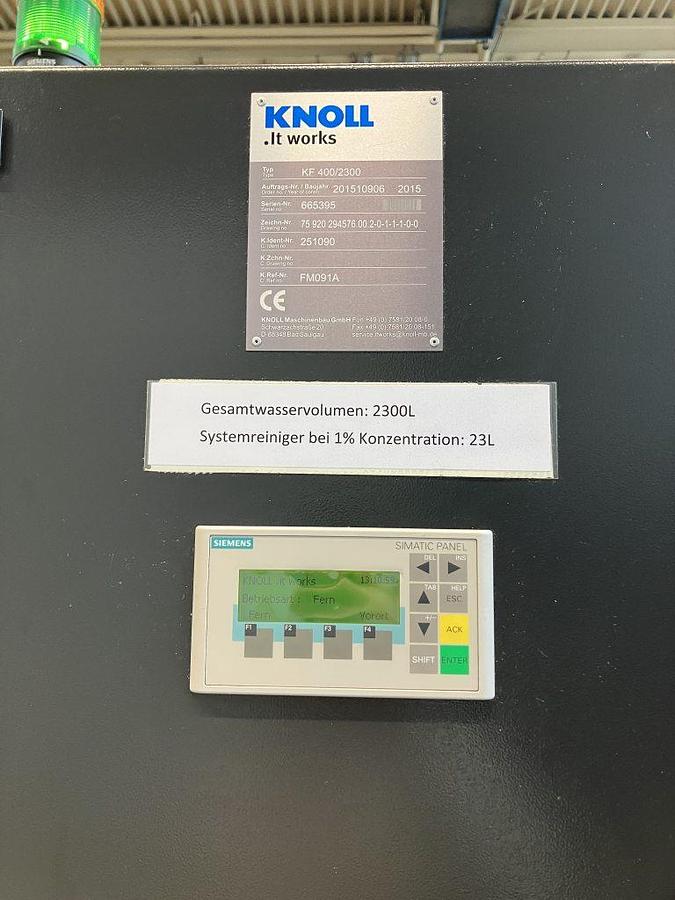

Knoll compact filter KF400/2300 (filtration capacity 400 l/min, tank volume 2300 l/min) 1)

High-pressure cooling 70 bar, 7 pressure stages

Chip conveyor, hinged belt design

Additional M-codes: 1 set = 2 M-codes

Preparation for dual extraction system (mechanical nozzle) 0.198 mm

Transformer for the European market

1 set of manuals in electronic form on CD

1 set of adjustment tools

Foundation set (anchor bolts + plates)

MAZAK standard paint

Work area lighting

Additional items:

AirFresh FMN V12 extraction system (installed on both sides and coupled with a door sensor)

Holding device for vertical operation of the rotary table

2 x Renishaw TS27R integrated tool presetting devices

Spare parts:

Y-axis motor, tool magazine

Linear axis shifter motor

Rotary axis shifter motor

Cylinder for swivel unit

Specifications

| Manufacturer | Mazak |

| Model | VTC 800/30SR |

| Year | 2016 |

| Condition | Used |

| Stock Number | VTC800-30SR |

| width | 3500 mm |

| length | 820 mm |

| X-axis travel range | 3000 mm |

| Y-axis travel range | 800 mm |

| Traversal range Z-axis | 720 mm |

| min. distance spindle nose to table top | 140 mm |

| max. distance from spindle nose to table top | 860 mm |

| max. table load | 2500 kgf |

| B-axis | ± 110 degrees |

| Working spindle steep taper mount | Steep taper 40 collapses under load 155 tools HSK |

| Max speed | 18,000 RPM |

| Min. Drehzahl | 35 min-1 |

| Rated power | ( 100 % continuous operation) 33,0 kW |

| Emergency travel speed X-Y & Z axis | 50 m/min |

| Working table width | 3500 mm |

| Worktable length | 820 mm |

| Width of T-slots | 18 mm |

| Number of T-slots | 7 |

| Distance of T-slots | 100 mm |

| Table height from the floor | 870 mm |

| Tool changer number of tool places (Standard) | 30 |

| Number of tool stations (optional) | 48 |

| Tool selection method | shortest path |

| tool shank | Steep cone 40 |

| With occupied side positions | 80 mm |

| With available spaces | 130 mm |

| max. tool weight | 8kgf |

| Total weight of all magazine tools | 150 kgf |

| max. tool length | 350 mm |

| Tool change time | (Span-to-Span) 4.7 s |

| Connected load | 400 V / 50/60 Hz |

| Air pressure | 5 – 9 bar |

| Air volume | 260 l/min |

| Tank capacity | 500 l |

| Dimensions (Height x Length x Width) | 3376 x 5480 x 4051 mm |

| Weight approx | 16300 kg |

| colour | Gray / Black |